Plant outage

Location: Alberta

Year: 2020

Scope: Tank Inspection Visual (API 653), Vessel Inspection (API 510), MPI, UT, PT and MFL

Description: Q Test supplied inspectors and technicians for regulatory plant outages.

Major Pipeline Project

Location: Fox Creek Area

Year: 2021-2022

Scope: Radiographic Testing

Description: Team of 20 personnel on site for providing nondestructive testing for a 670km pipeline common ditch 16” & 12”. Q Test provided mainline crews, poor boy crews, Tie-in crews, fabrication crews and a crawler crews.

Pipeline Quality Assurance

Location: Edmonton

Year: 2019-2020

Scope: RT/MT/PT/VT, Provide Quality Assurance, Inspection and NDT for valve replacement program and line abandonment.

Description: Q Test Inspection provided quality assurance inspectors, coating inspectors and Engineering support. Q Test Inspection managed the quality program, monitored welding and coating activities, perform parameters, conducting visual inspections and performing coating inspection.

Lifting Equipment Inspection

Location: Alberta

Year: 2022

Scope: Lifting Equipment Inspection of various models of cranes and equipment.

Description: Q Test provided personnel with certifications to CWB I and CGSB MT II to inspect lifting equipment.

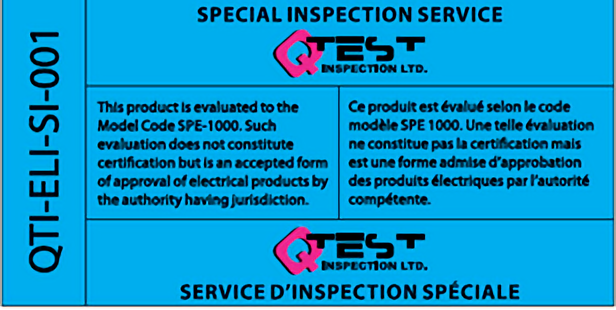

CSA / Special Inspection Services

Location: Central Alberta

Year: 2021

Scope: Inspection of custom panels

Description: Perform special inspection services and evaluate equipment for conformance to SPE-1000 and Canadian Electrical Code (CEC).

Pipeline Quality Assurance

Location: Throughout British Columbia

Year: 2021

Scope: Quality Assurance and Quality Auditing

Description: Q Test Inspection provided quality assurance representatives for the mechanical scope and performed quality audits on contractors.

Piping, Tank and Vessel Inspections

Location: Alberta

Year: 2021

Scope: API Inspections and NDT

Description: Provided an inspection crew with certification to API 510, 653 and 570, as well as, CGSB MT II/UT II to inspect piping, tanks and vessels.

Chief Inspection and NDT

Location: Alberta

Year: 2018-Ongoing

Scope: Chief Inspection and NDT Services

Description: Liaise with regulatory bodies, provide regulatory consulting, maintain ABSA program, pipeline integrity support and nondestructive testing (UT MT).

Pipeline Quality Control

Location: Central Alberta

Year: 2019

Scope: Quality Control and Engineering

Description: Perform visual inspections, manage quality program, yield plot testing, engineering and design of test heads and pig launcher and receivers.

Flowline Construction

Location: Alberta

Year: 2020-2022

Scope: Nondestructive Testing

Description: Perform Radiographic Testing, Magnetic Particle, UT and Hardness inspection on new installation of above ground steam and flow lines at a SAGD construction site.

A turnaround is a highly expensive planned period of regeneration in a plant or refinery. During this time, an entire part of the operation is offline, whilst plants are inspected and revamped. Not only are the tools and labor required for executing a turnaround extremely expensive, but the revenue lost through shutting down elements of production can amount to a significant portion of an annual budget. Turnarounds often throw up more issues than anticipated, making them difficult to keep on track, and requiring very experienced managers and inspectors.

Q Test Inspection has many years of experience on Turnarounds and Shutdowns. Q Test can supply you with NDT, Inspection and Engineering resources required to help you stay on-schedule and keep your Turnaround or Shutdown running smoothly and efficiently.